Industrial Robotic Palletizing

Robotized Palletizing - Benefits:

Precise Palletizing of Bulk Materials

Our advanced technologies enable palletizing of bulk materials such as bitumen mass and salt tablets, ensuring load stability and minimizing losses during transport.Robotic Palletizing Stations for Bagged Products

We offer automated solutions for palletizing bags of eco-pea coal and pellets of various weights, equipped with fork grippers and pallet magazines, ensuring a fast and safe process.In-Company Transport

Our systems include chain and roller conveyors for pallets and boxes, optimizing logistics processes in production plants.Advanced Automation Systems

We use PLC controllers, HMI panels, and dedicated grippers, enabling full automation and customization of the palletizing process tailored to specific customer needs.

Advanced Palletizing and Automation Technologies for Industry

At Domasz Robotics, we provide advanced palletizing and automation technologies for various industries, including bitumen mass production, salt tablet packaging, in-company transport, and palletizing of pellets and eco-pea coal. Our systems are designed for precise stacking of diverse materials, regardless of their form and variability.

bituminous_mass.title

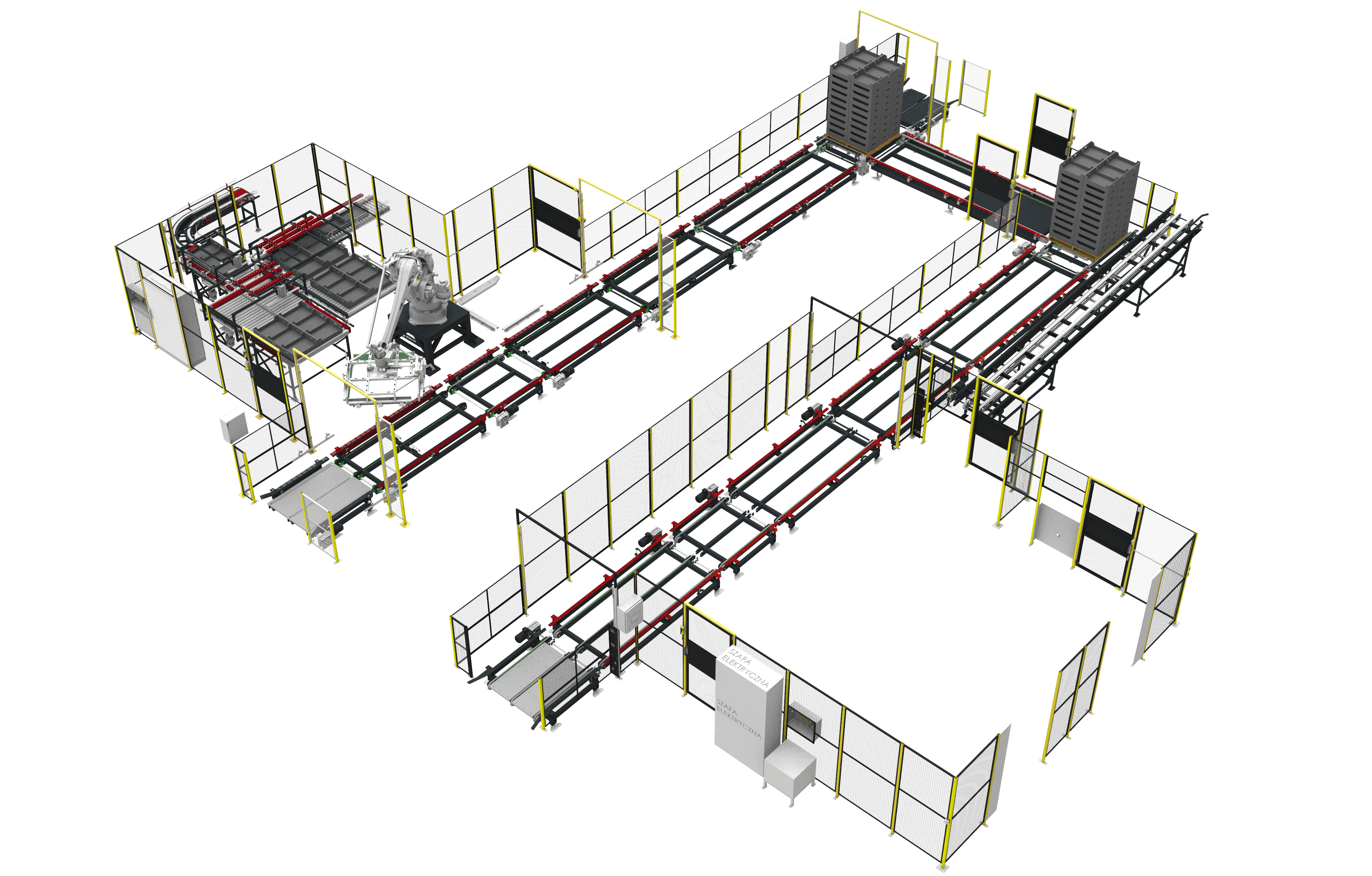

Transport of Various Pallet Sizes Between Halls Using Automated Pallet Crossings

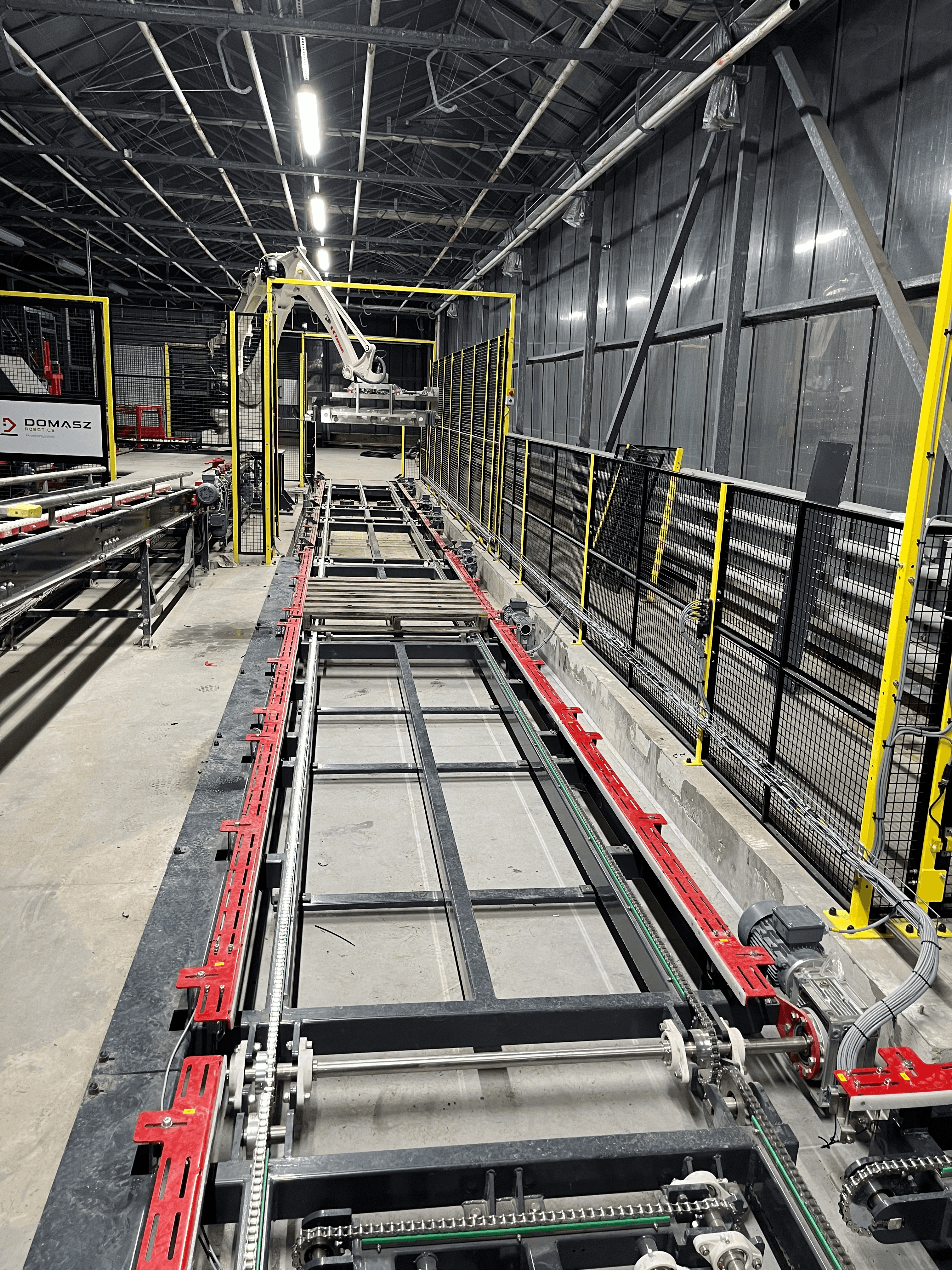

In-Company Transport

We offer advanced in-company transport systems, including chain and roller conveyors for pallets and boxes, which streamline material flow. For larger facilities, autonomous vehicles are available to enhance internal transport. Our solutions provide full integration with palletizing systems, increasing efficiency and reducing downtime.

We offer advanced in-company transport systems, including chain and roller conveyors for pallets and boxes, which streamline material flow. For larger facilities, autonomous vehicles are available to enhance internal transport. Our solutions provide full integration with palletizing systems, increasing efficiency and reducing downtime.

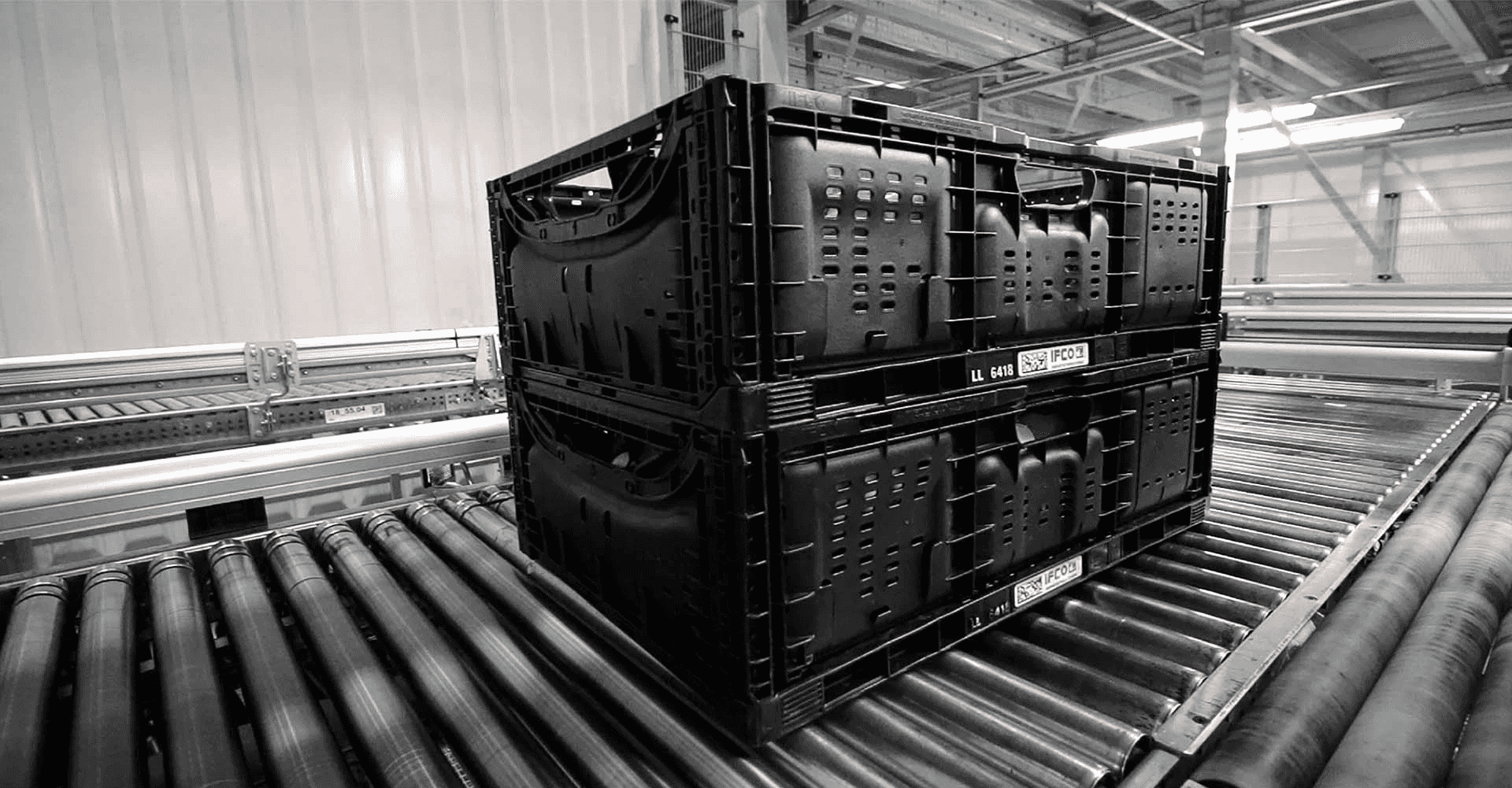

Handling and transportation of IFCO boxes and more

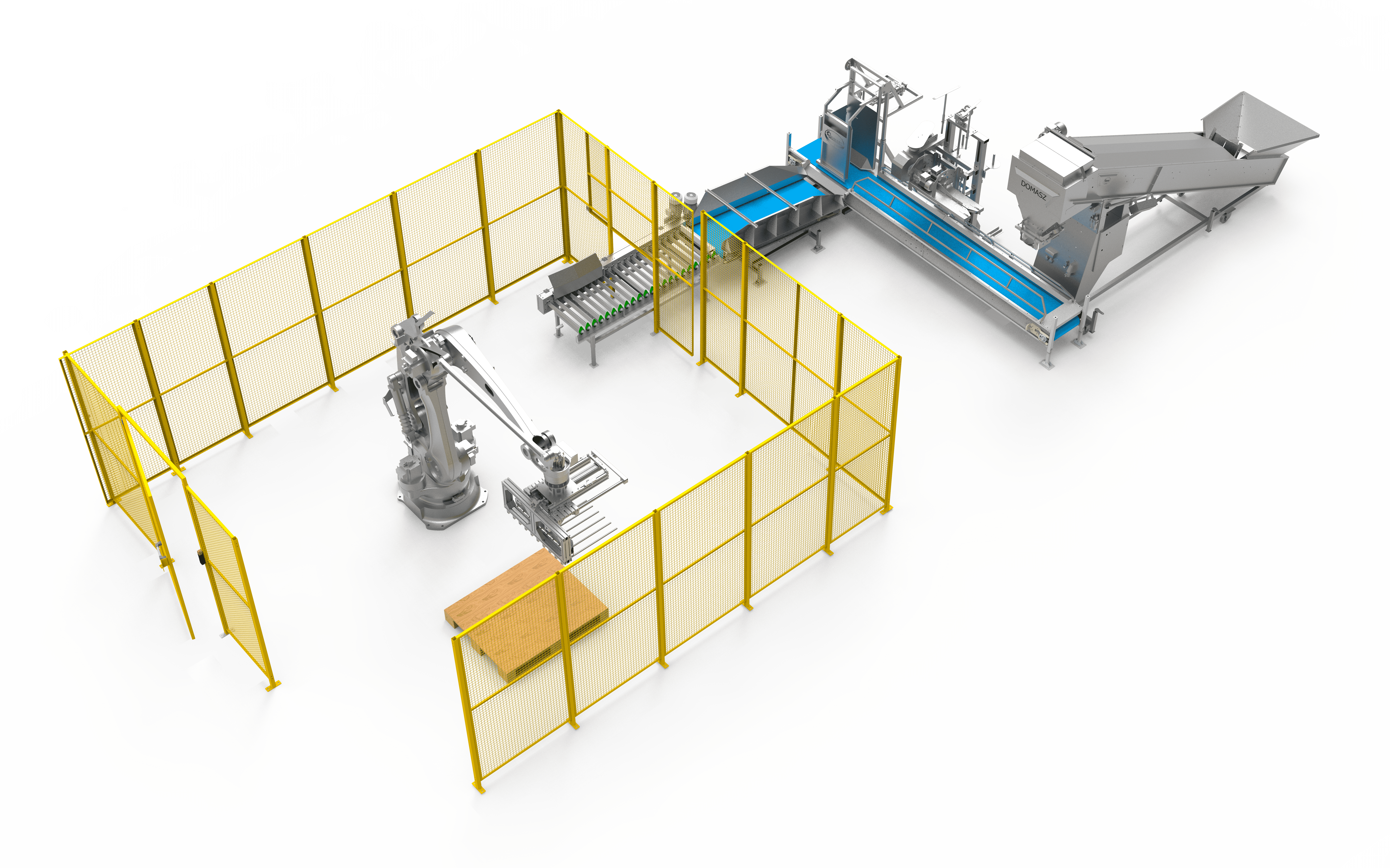

Bulk Material Palletizing Station

The Robotic Workstation Includes:

- Industrial Robot

- Gripper dedicated to the specific application

- Transport - including roller conveyors, belt conveyors

- Safety components - including safety controllers, enclosures

- Automation components - including control systems, HMI panel, PLC controller

Stable Palletizing of Bulk Materials

For bulk materials such as bitumen mass or salt tablets, our solutions ensure load stability on pallets, minimizing the risk of damage and material loss. Robotic palletizing stations are equipped with dedicated grippers that precisely adapt to the specific requirements of each application.

Palletizing of products such as eco-pea coal and pellets is performed using a fork gripper, ensuring precise stacking of bags on pallets and minimizing the risk of damage during transport. An automatic pallet magazine and full pallet buffering systems further optimize the process, increasing efficiency and flexibility.

Pellet Bag Palletizing Station

Palletizing of pellet bags weighing 15 and 25 kg is carried out using a fork gripper. The process includes manual loading of empty pallets, onto which the bags are then automatically stacked. After stacking, full pallets are manually collected. The fork gripper ensures precise and safe stacking of bags on pallets, which is crucial for stability and efficiency in transport and storage.

Palletizing of pellet bags weighing 15 and 25 kg is carried out using a fork gripper. The process includes manual loading of empty pallets, onto which the bags are then automatically stacked. After stacking, full pallets are manually collected. The fork gripper ensures precise and safe stacking of bags on pallets, which is crucial for stability and efficiency in transport and storage.

Eco-pea Coal Palletizing Station

Equipped with a weighing bagging machine that fills polypropylene bags weighing 25 kg. The bags are then moved using a sliding gripper. The workstation has a magazine that holds 15 empty pallets, each of which automatically moves into the palletizing area. After stacking the bags, the full pallet is automatically transported to a buffer area for temporary storage before further transport.

Equipped with a weighing bagging machine that fills polypropylene bags weighing 25 kg. The bags are then moved using a sliding gripper. The workstation has a magazine that holds 15 empty pallets, each of which automatically moves into the palletizing area. After stacking the bags, the full pallet is automatically transported to a buffer area for temporary storage before further transport.

Automation and Safety in Palletizing Processes

Each workstation includes automation components such as PLC controllers, HMI panels, and advanced safety systems that ensure full control over the process and operator safety. Our transport systems, including chain and roller conveyors, can be adapted for transporting pallets, boxes, or cartons, significantly improving material flow in production plants.

Machines and projects implemented for our clients are insured by Warta.

DOMASZ ROBOTICS Sp. z o. o.

ul. Centralna 16

63-012 Dominowo

Wrocław department

ul. Prosta 36C

53-508 Wrocław

Kamil Mandrela

Machinery Specialist

+48 797 628 965

Agata Mazelle

Administration specialist

+48 789 166 923