Palletization in Horticulture

Palletization – Benefits:

Increasing production efficiency

Thanks to the automation of palletizing and depalletizing processes.Protection of delicate products

By precisely and safely handling tulips.Solutions tailored to your needs

Custom machine design for maximum efficiency.Resistance to difficult environmental conditions

Our devices are reliable even in demanding conditions.

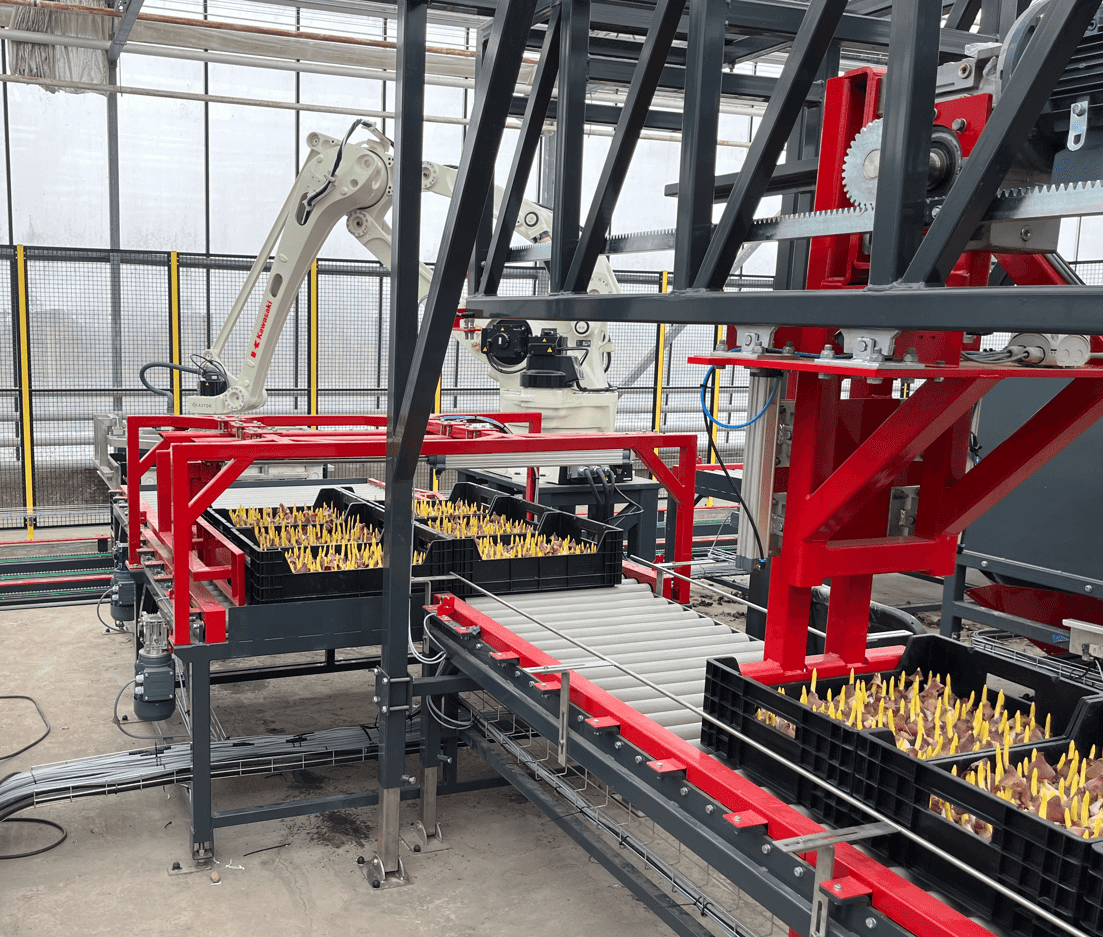

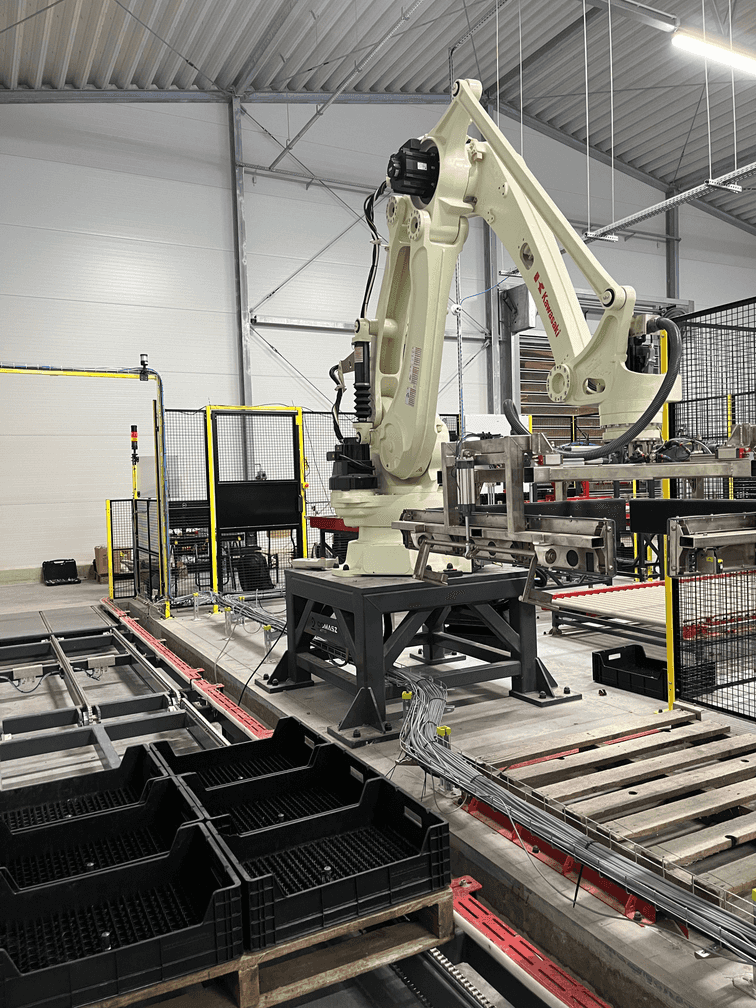

Palletization and depalletization in horticulture

In the horticultural industry, precision and delicacy are key. Our industrial robot palletizers are perfect for automating processes while ensuring the utmost care for your products. Regardless of the type of packaging, we guarantee high efficiency and safety by adapting solutions to prevailing environmental conditions.

On our production lines, we use machines and solutions designed specifically for you. Each device meets the highest quality standards to fulfill the individual requirements of your business.

On our production lines, we use machines and solutions designed specifically for you. Each device meets the highest quality standards to fulfill the individual requirements of your business.

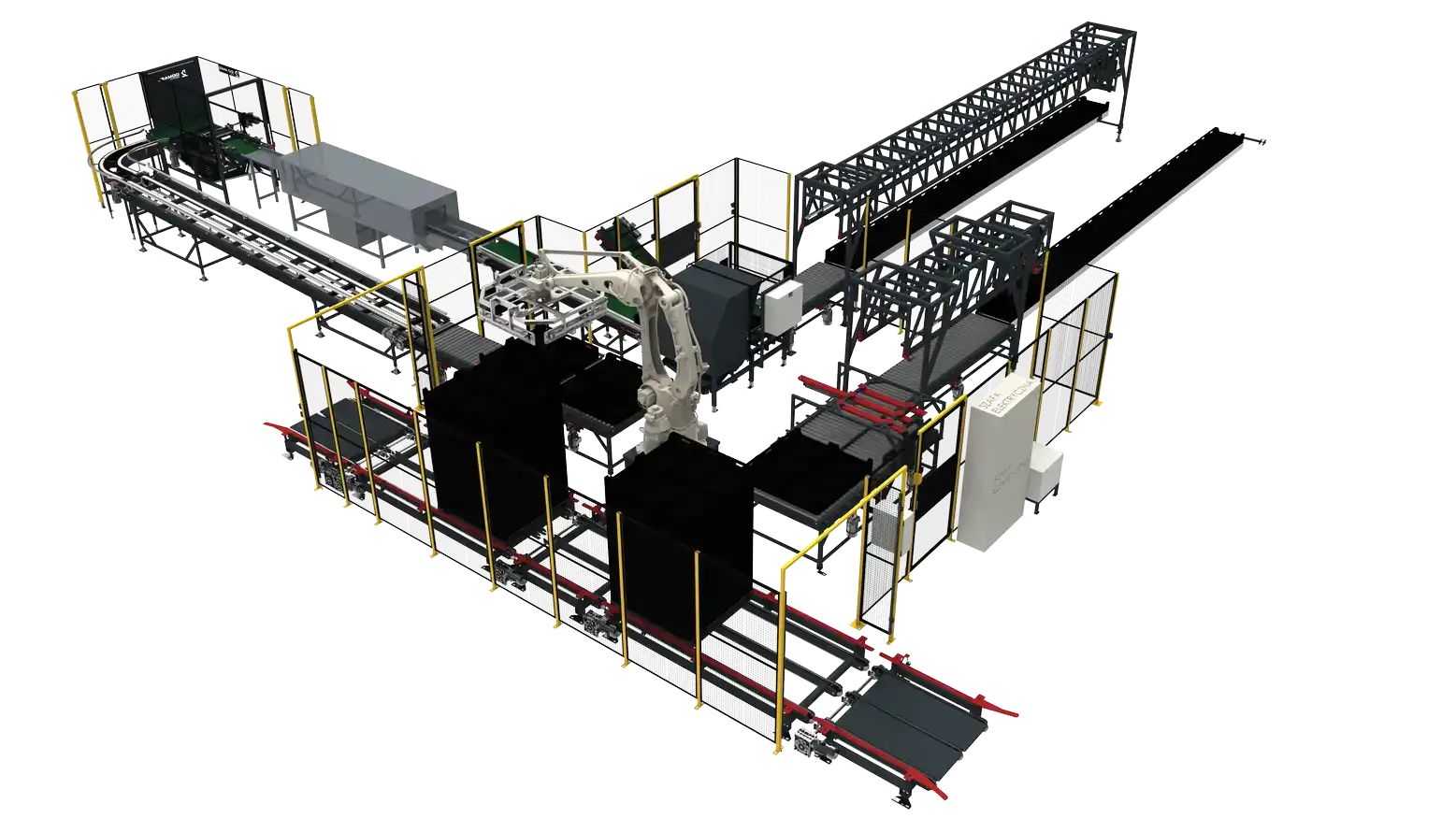

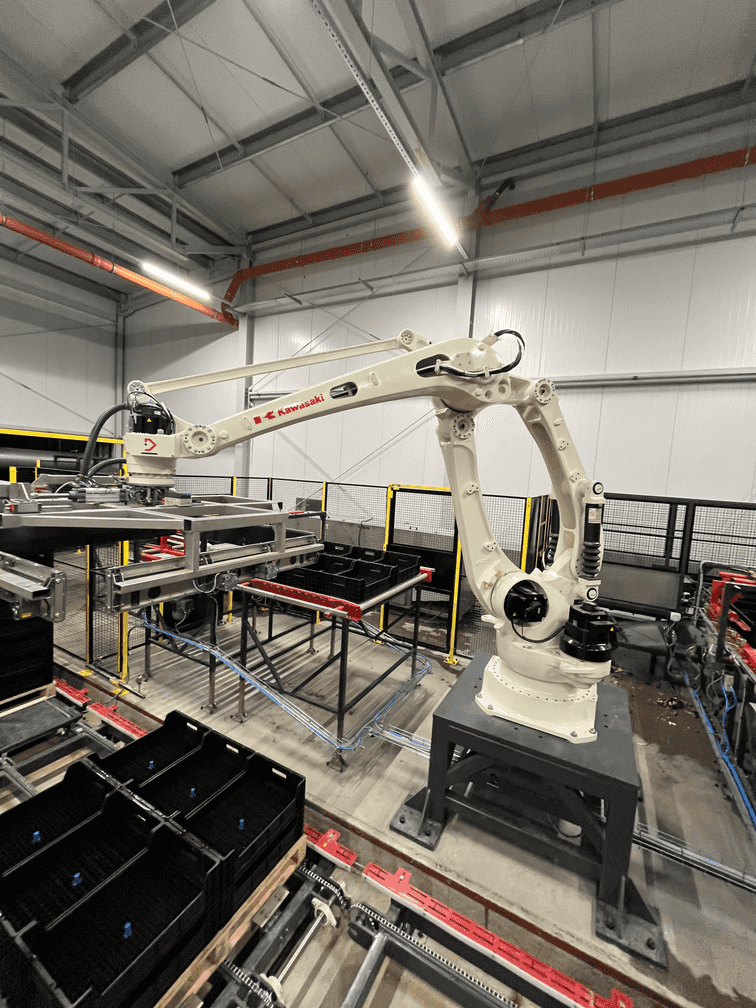

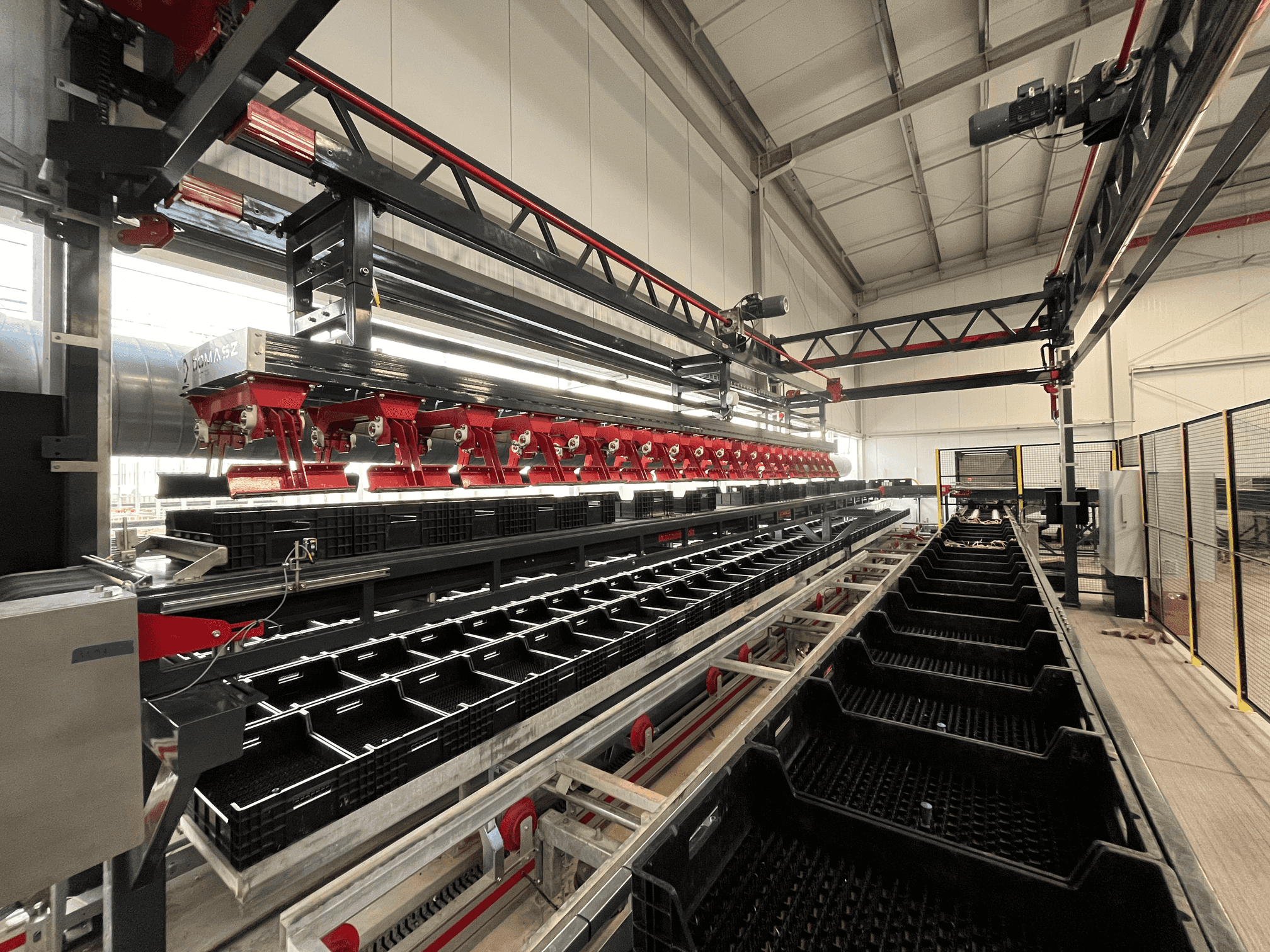

Technological Line for Greenhouse Service

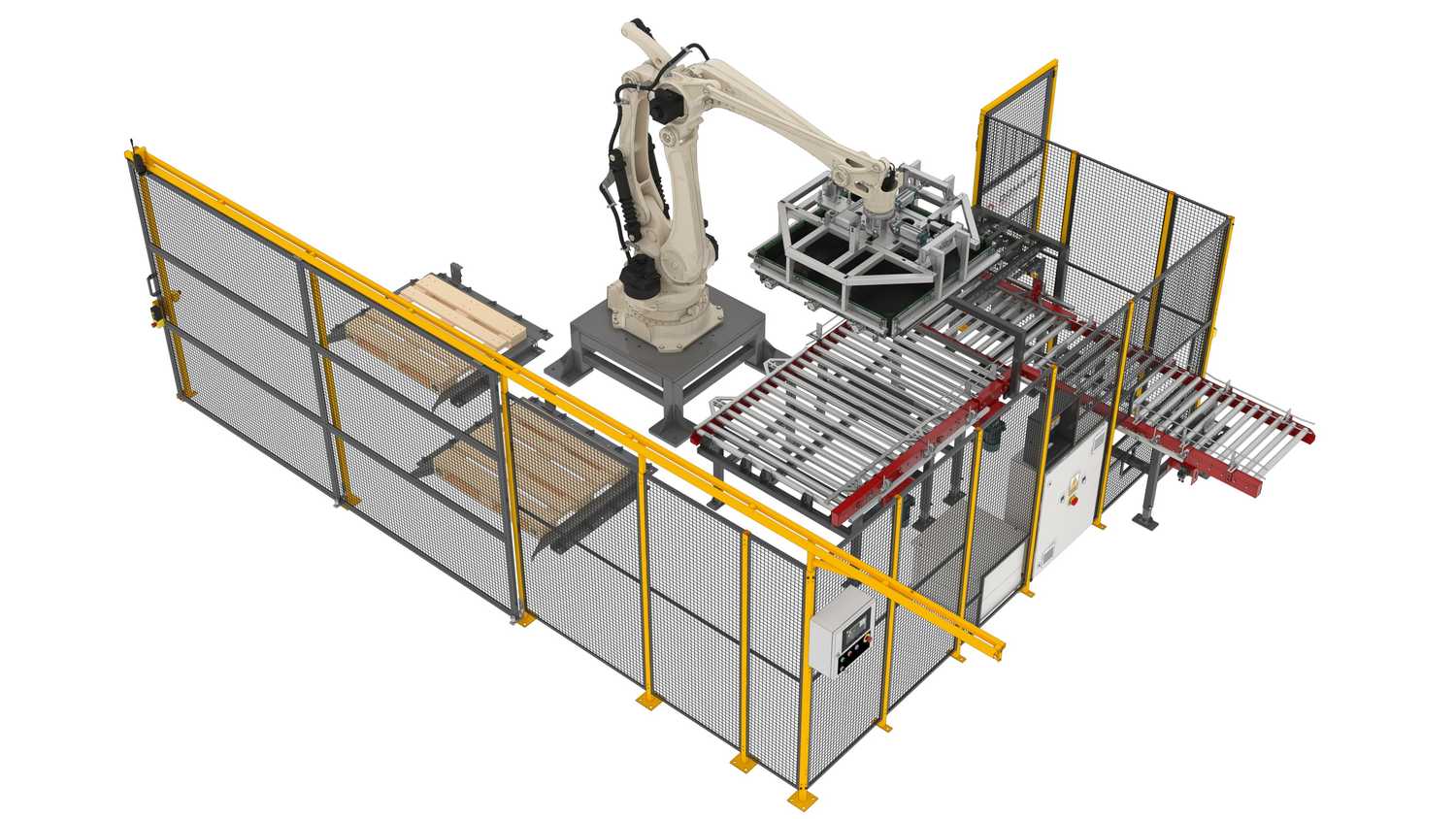

Our robotic greenhouse servicing line includes:

- Greenhouse box pusher

- Device for emptying dirty boxes

- Box flipping devices

- Weather-resistant box transporters

- Pallet transporters with stainless steel chains

- Kawasaki industrial robot with performance tailored to your greenhouse

By using an industrial robot, we offer a wide range of adjustments, and the intuitive touchscreen allows you to create your own palletizing recipes. Operator safety is fully guaranteed thanks to SICK Safety components.

Many years of cooperation with our first clients have been continuously developed, ensuring that our gardening solutions are refined and resistant to environmental impacts in critical areas.

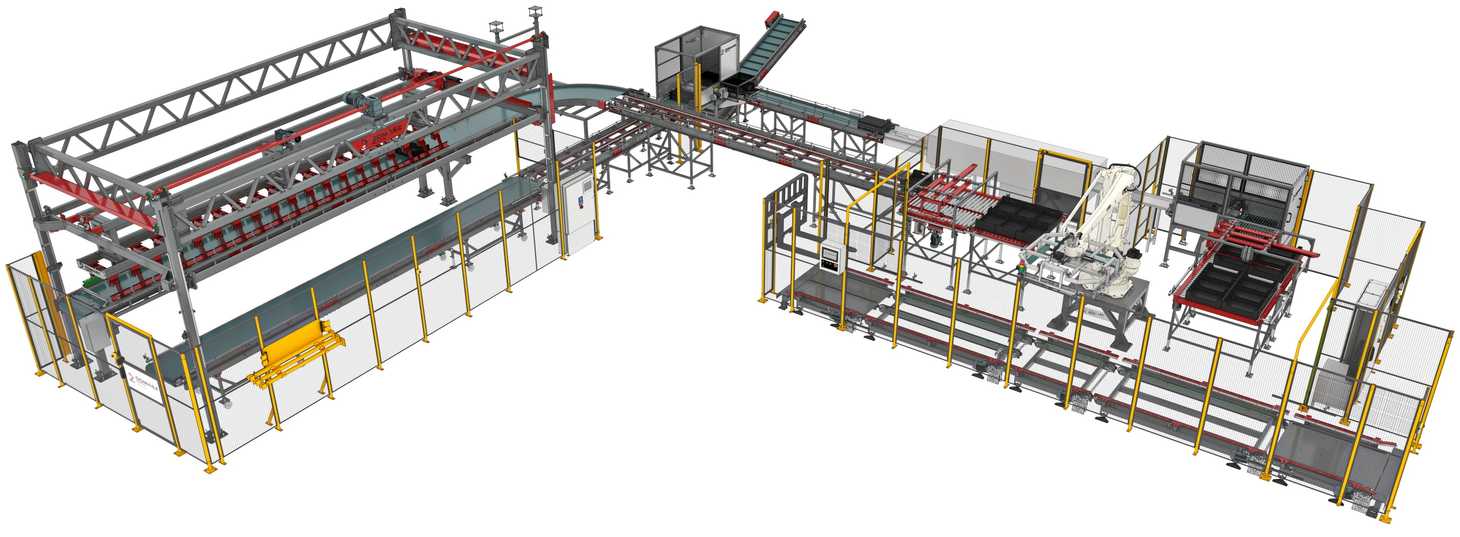

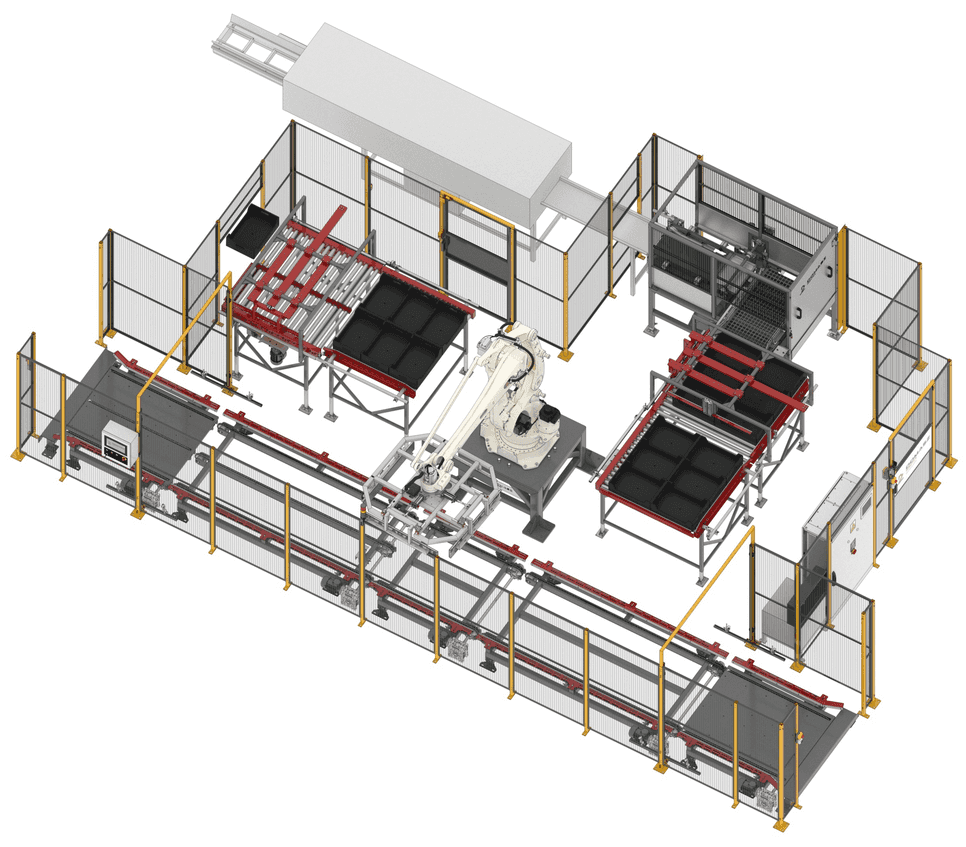

Technological line for operating an automatic bulb planting machine – another project at Polskie Tulipany and a continuation of the greenhouse servicing line.

Main processes we handle:

- Pallet transport with crates – stainless steel chain conveyors and pallet crossings

- Depalletization of empty technological crates

- Pallet buffering

- Picking up empty pallets from a stack using a robot

- Assembly and disassembly of technological crates

- Palletization of full crates onto pallets

- Automatic pallet exit

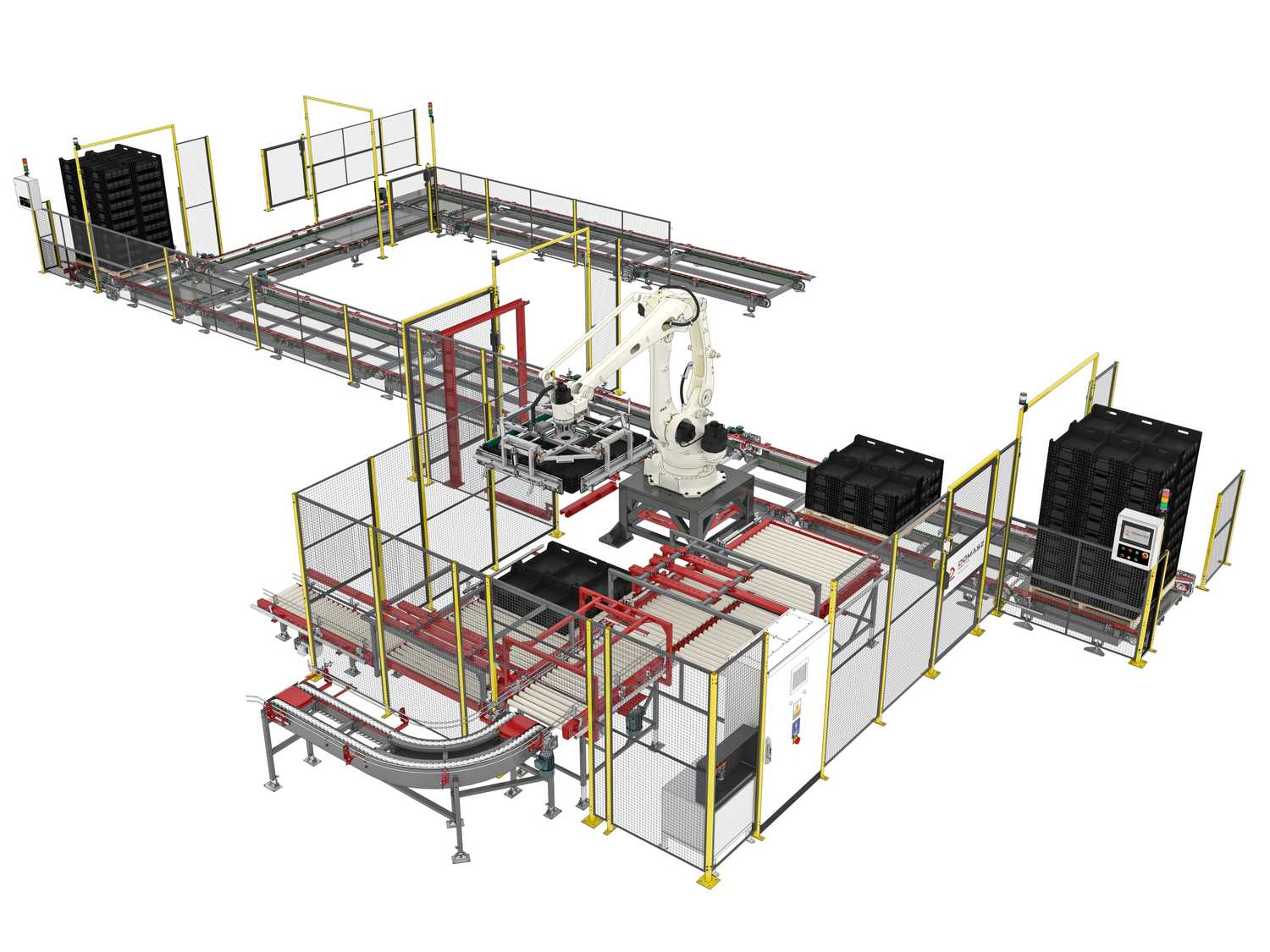

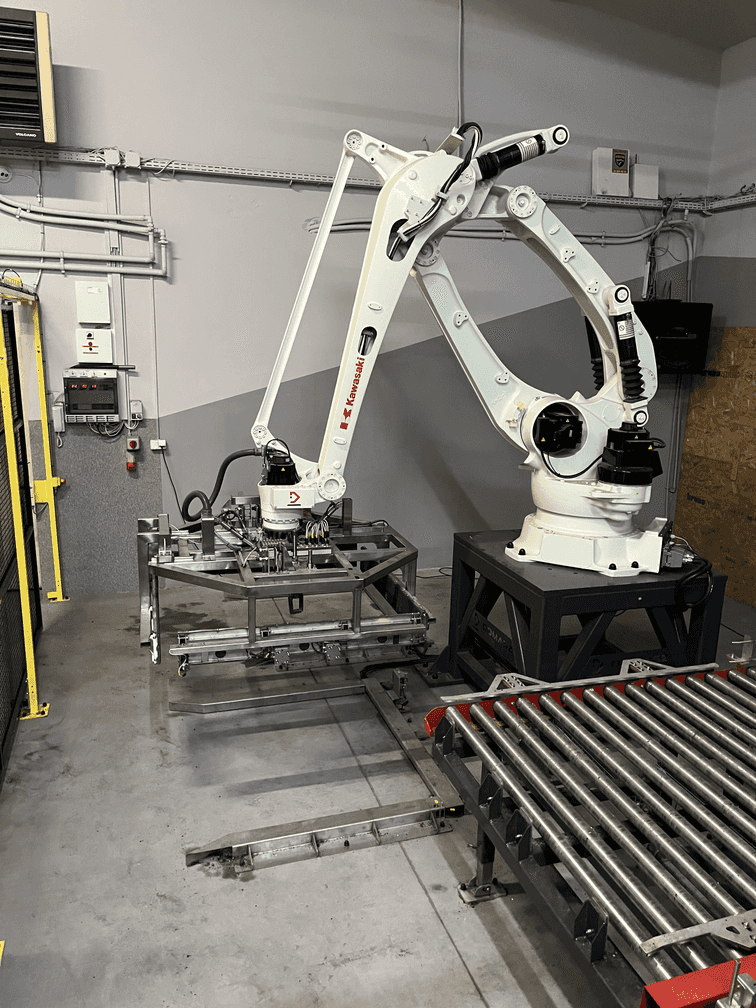

Palletizing station for crates at Gospodarstwo Ogrodnicze Wolscy

Main processes we handle:

- Receiving crates from the planting machine

- Assembly of technological crates

- Palletizing full crates of various heights onto pallets

- The operator manually receives and inserts pallets

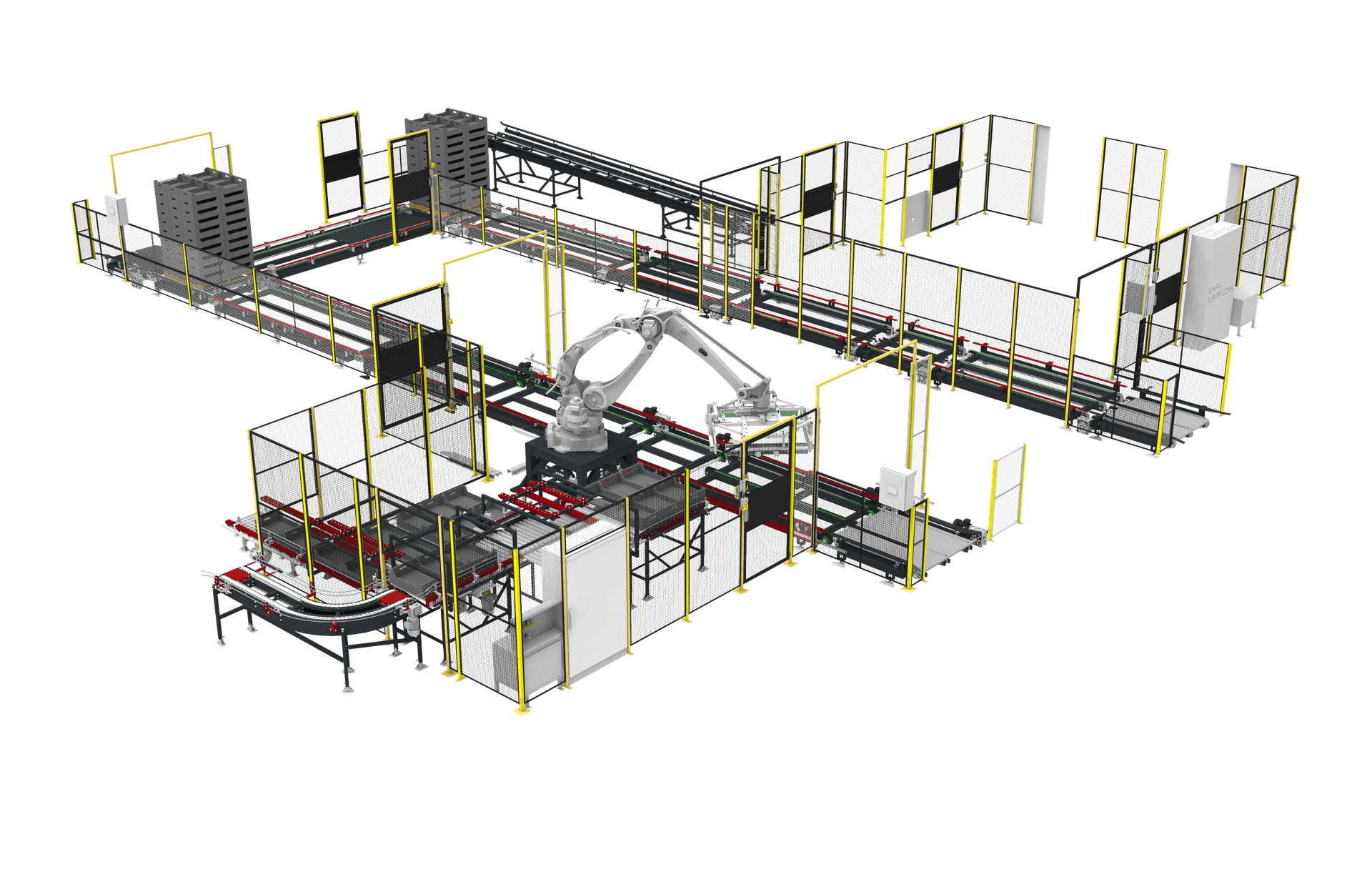

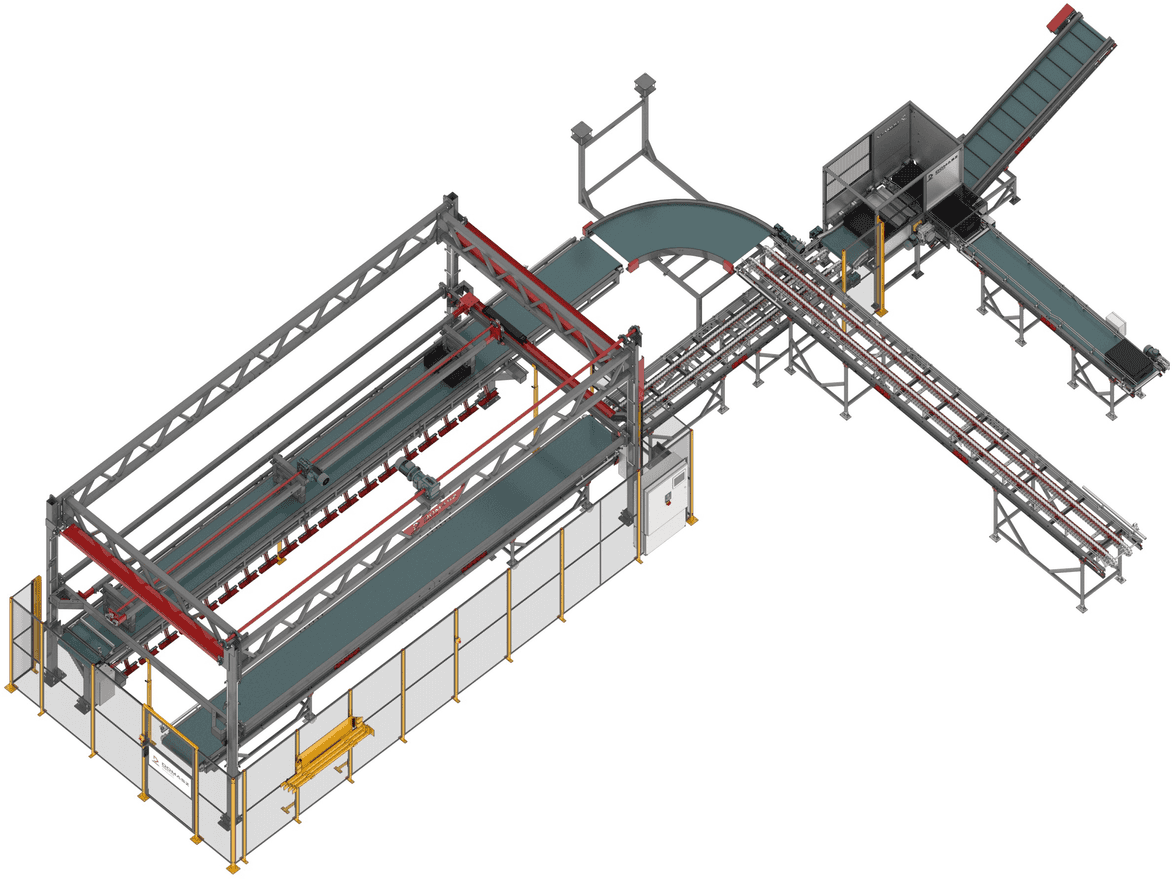

Technological line for greenhouse operation at Nowacki Tulipany

Main processes we handle:

- Receiving dirty crates from the greenhouse and loading full crates into the greenhouse – communication with the greenhouse

- Shaking out crates

- Transporting crates to the washer and flipping them

- Assembly of empty crates and disassembly of full crates

- Palletization and depalletization of crates using an industrial robot

- Automatic pallet transport – option to introduce closed pallets onto the chain conveyor

Machines and projects implemented for our clients are insured by Warta.

DOMASZ ROBOTICS Sp. z o. o.

ul. Centralna 16

63-012 Dominowo

Wrocław department

ul. Prosta 36C

53-508 Wrocław

Kamil Mandrela

Machinery Specialist

+48 797 628 965

Agata Mazelle

Administration specialist

+48 789 166 923