Fruit and vegetable palletizing system

Palletizing system – key benefits:

Increased efficiency

The robotic station allows simultaneous crate pick-up from multiple tables and placement on different pallets, significantly speeding up the palletizing process.Operational flexibility

The system adapts to different crate types (IFCO, EPS, technological, cardboard), ensuring versatility and compatibility.Intuitive operation

Touchscreen interface enables easy creation of custom palletizing recipes, simplifying management and adaptation.Top-level safety

Use of advanced SICK Safety components guarantees full protection of operators and equipment.

Crate placement on pallets

Plastic and cardboard crates play an important role in industries such as food, medical, and automotive. A key logistic challenge in packing them is maximizing space efficiency while protecting product integrity during transport. Optimal crate placement on the pallet is critical for maintaining load stability and minimizing damage risks.

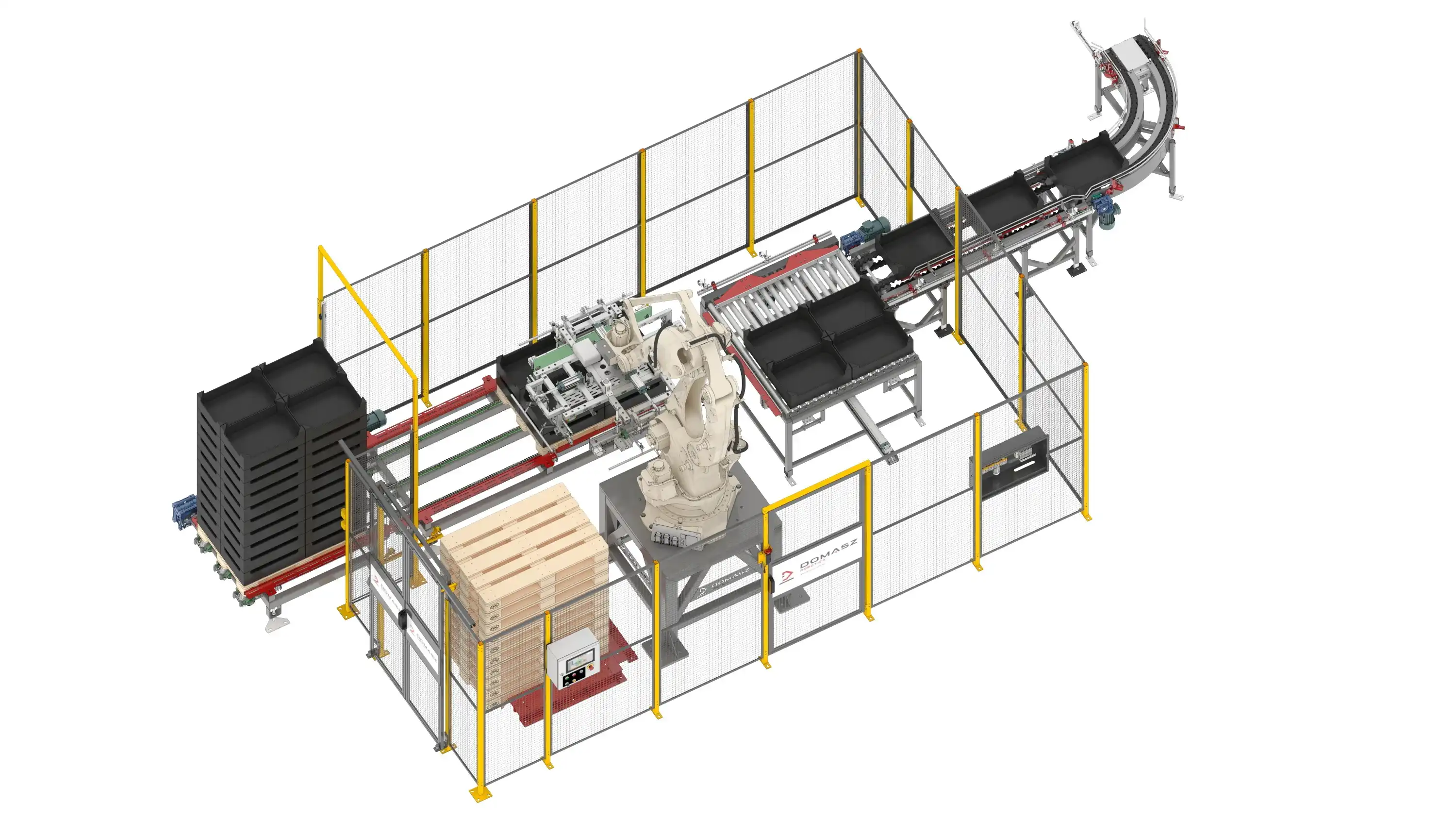

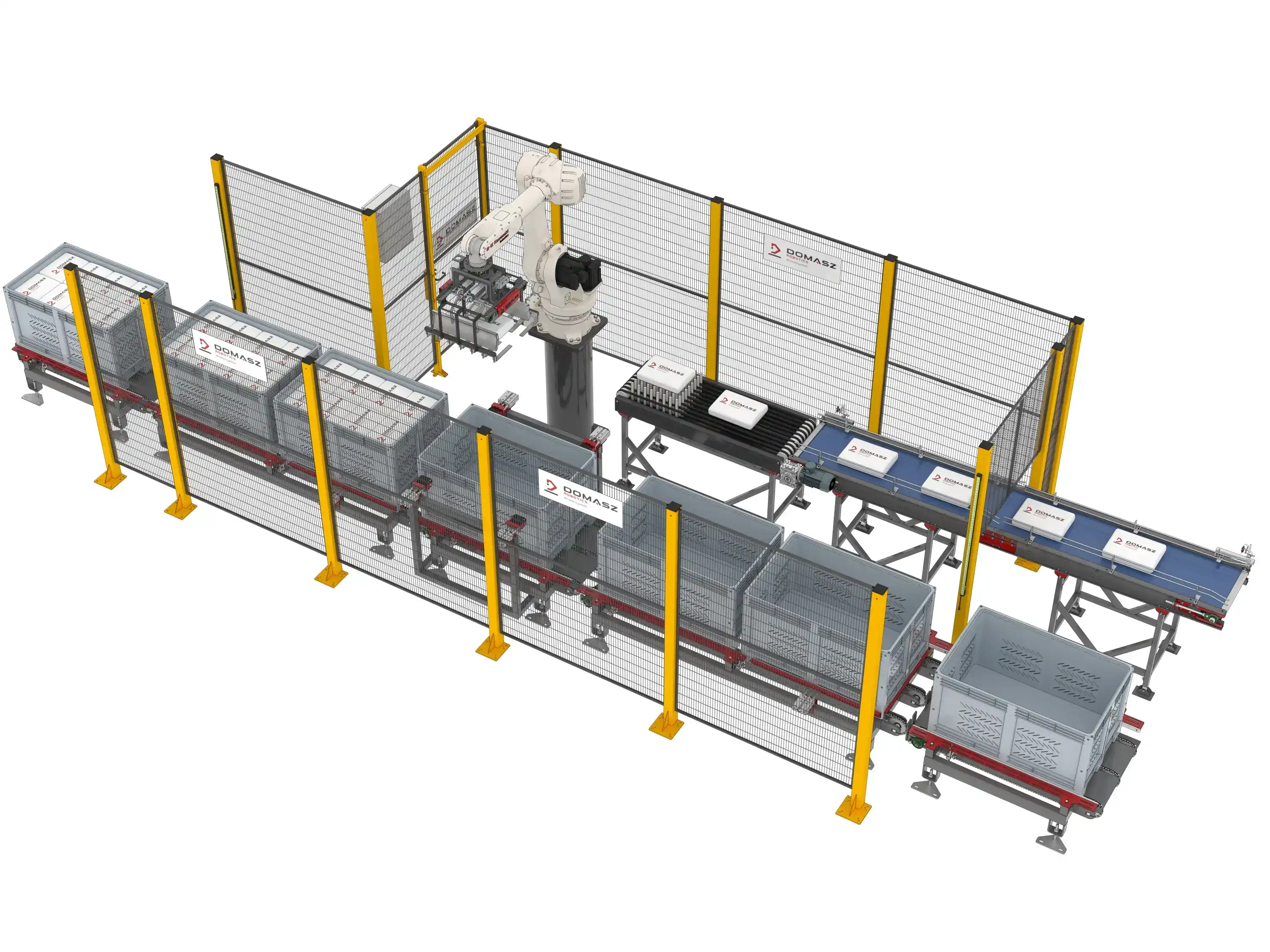

Single station for crate palletizing

Main benefits of the palletizing system

- High palletizing efficiency – the ability to pick crates from 4 tables and place on 4 pallets

- Flexibility – supports IFCO, EPS, technological, and cardboard crates

- Versatility – the robot can pick empty pallets from a stack

- Simple operation via touchscreen with recipe creation functionality

- Full operator safety through the use of SICK Safety components

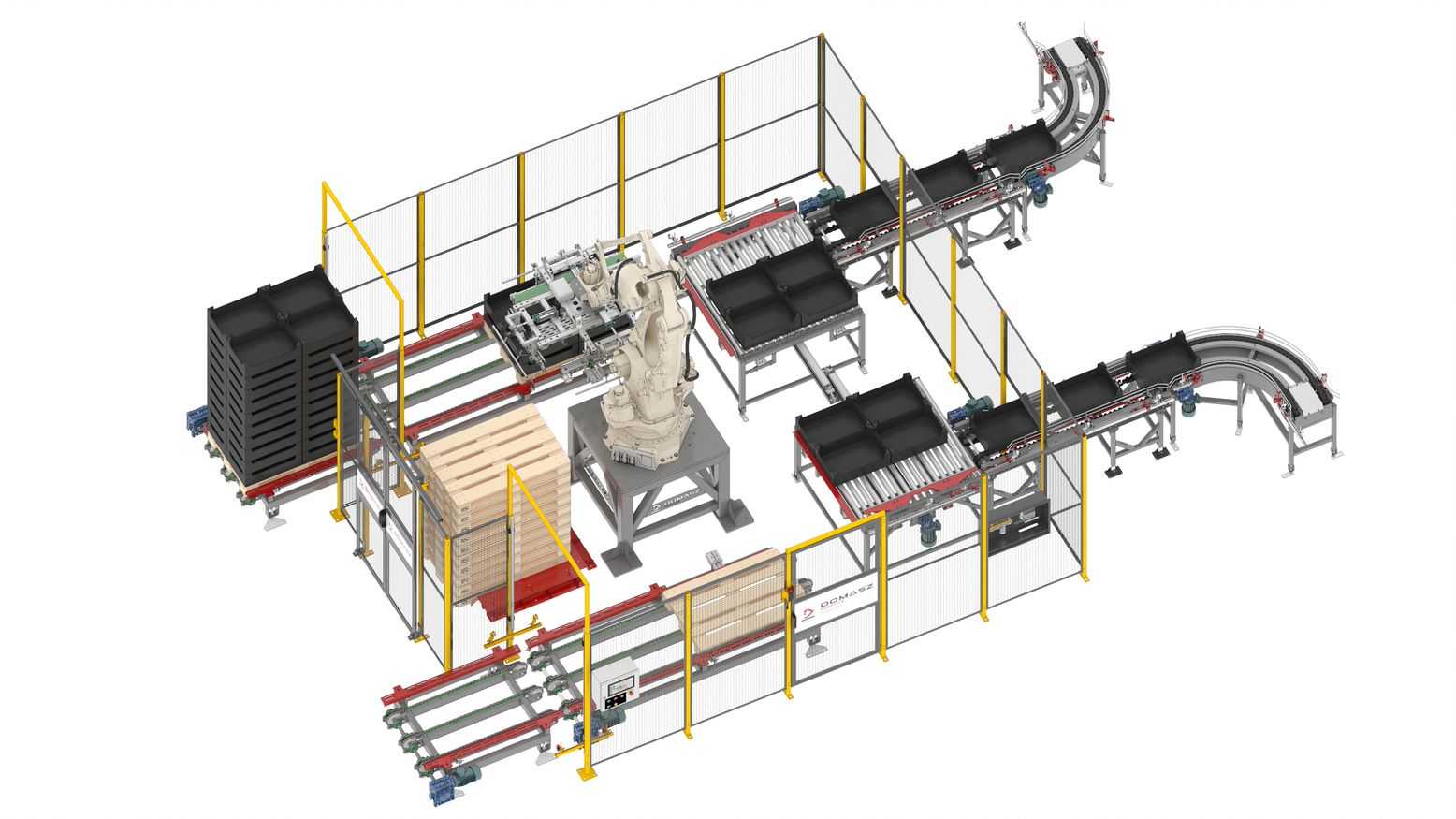

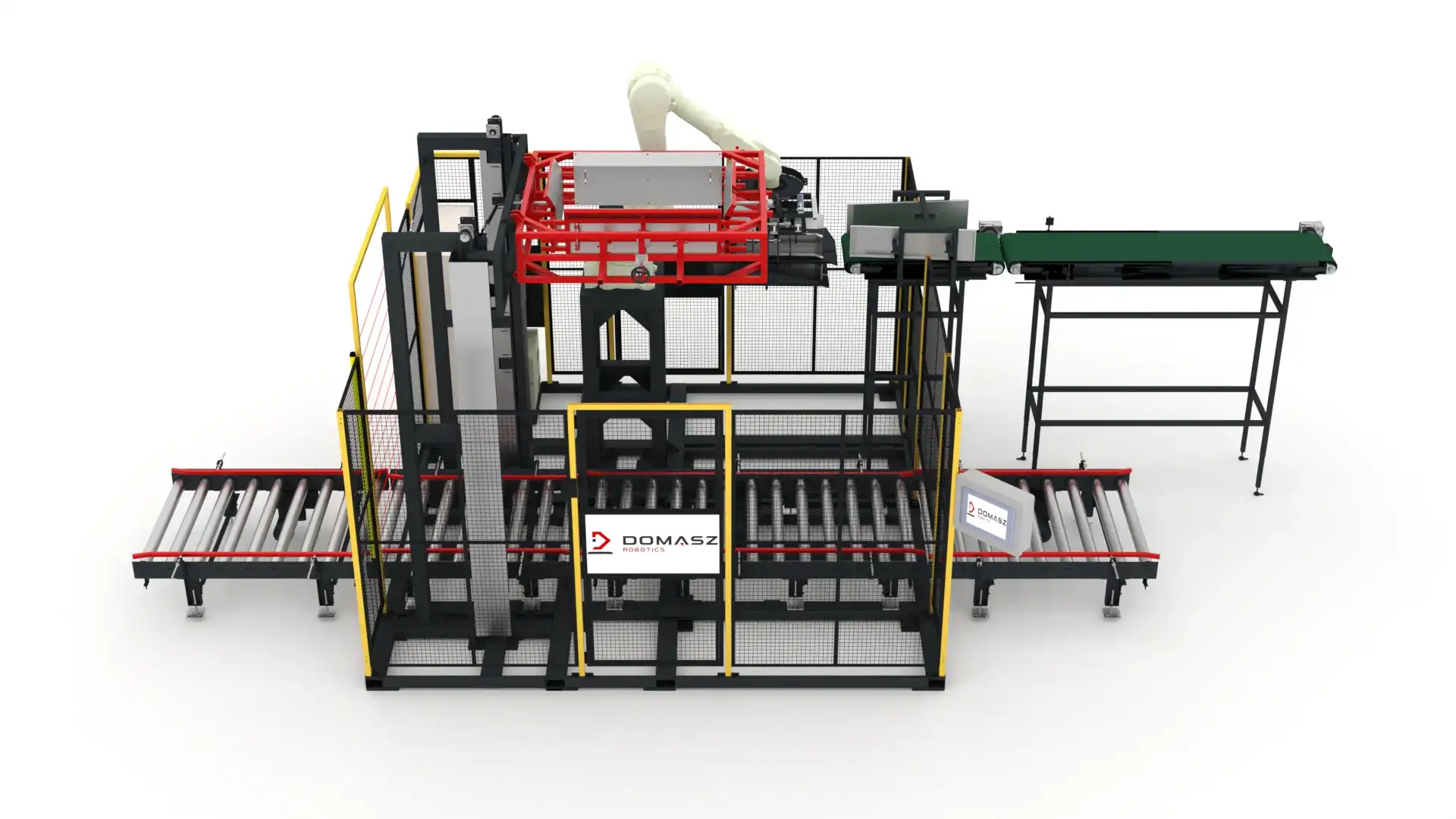

Double station for crate palletizing

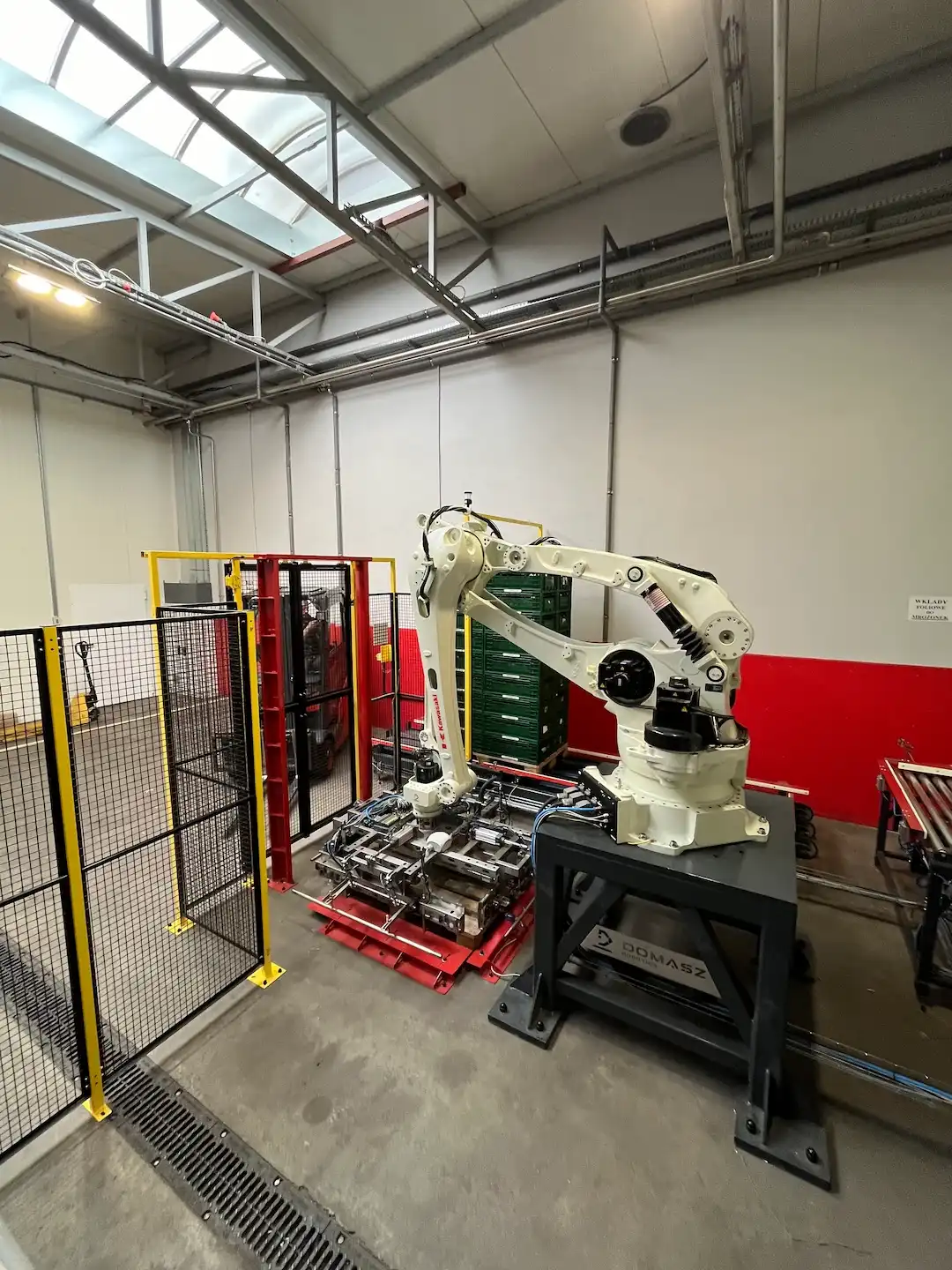

The robotic station for palletizing and depalletizing crates consists of:

- Industrial robot

- Gripper for picking full layers, ensuring high palletizing and depalletizing efficiency

- Safety components – including safety controller, laser curtains, industrial fencing

- Automation elements – including control, HMI panel, PLC controller

- Transport system for pallets and plastic crates

- Station customized to client’s layout and hall height

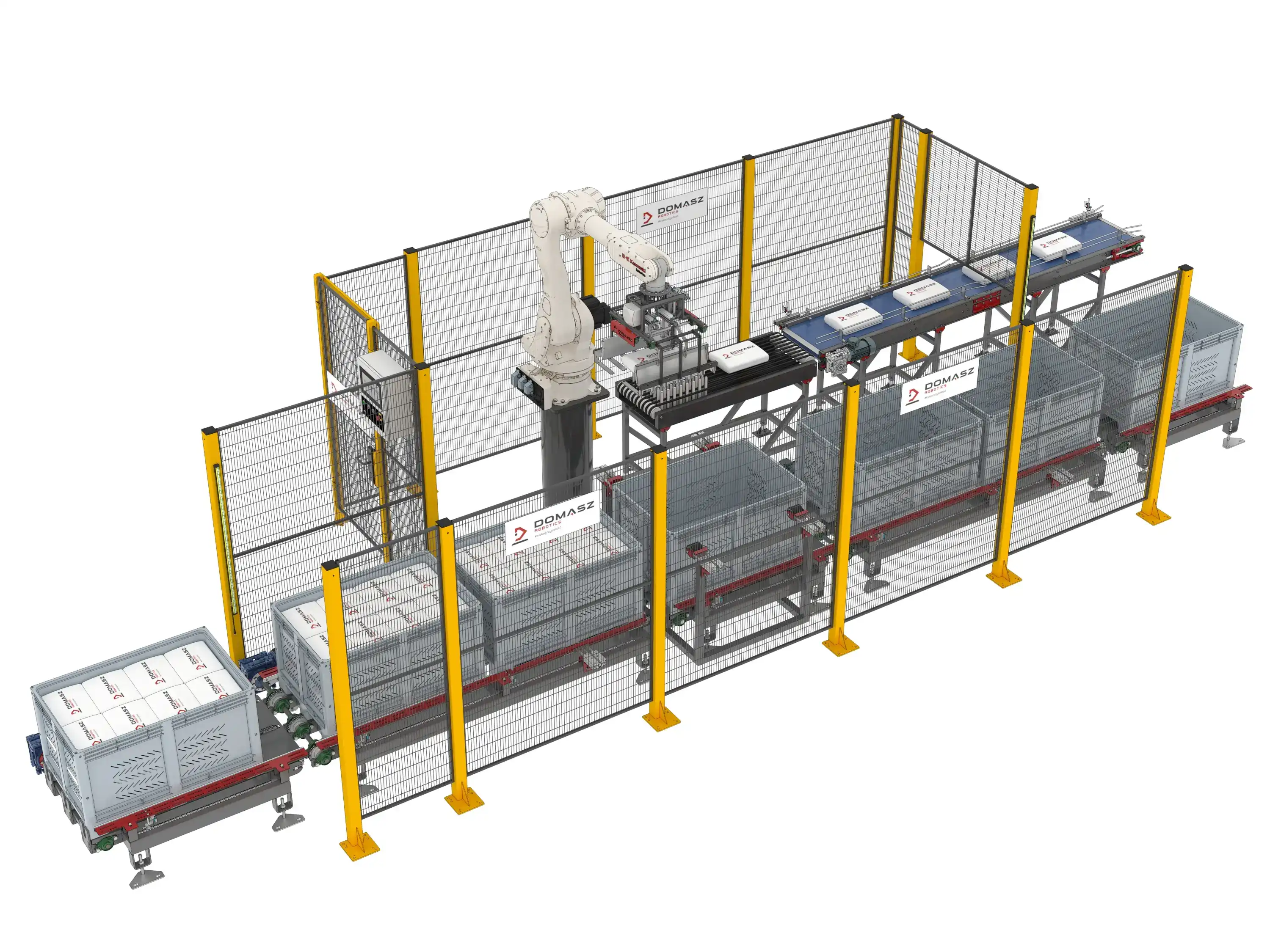

Packing into BINS

Key processes supported:

- Bag pick-up: 2.5–10 kg

- Supply of empty pallet containers

- Bundling and palletizing several bags at once

- Automatic pallet container transport

- Bin vibration

- Efficiency up to 40 bags/min (depending on packaging)

- Stacking of full containers possible

- Also possible to pack bags into IFCO, EPS, and CARDBOARD crates

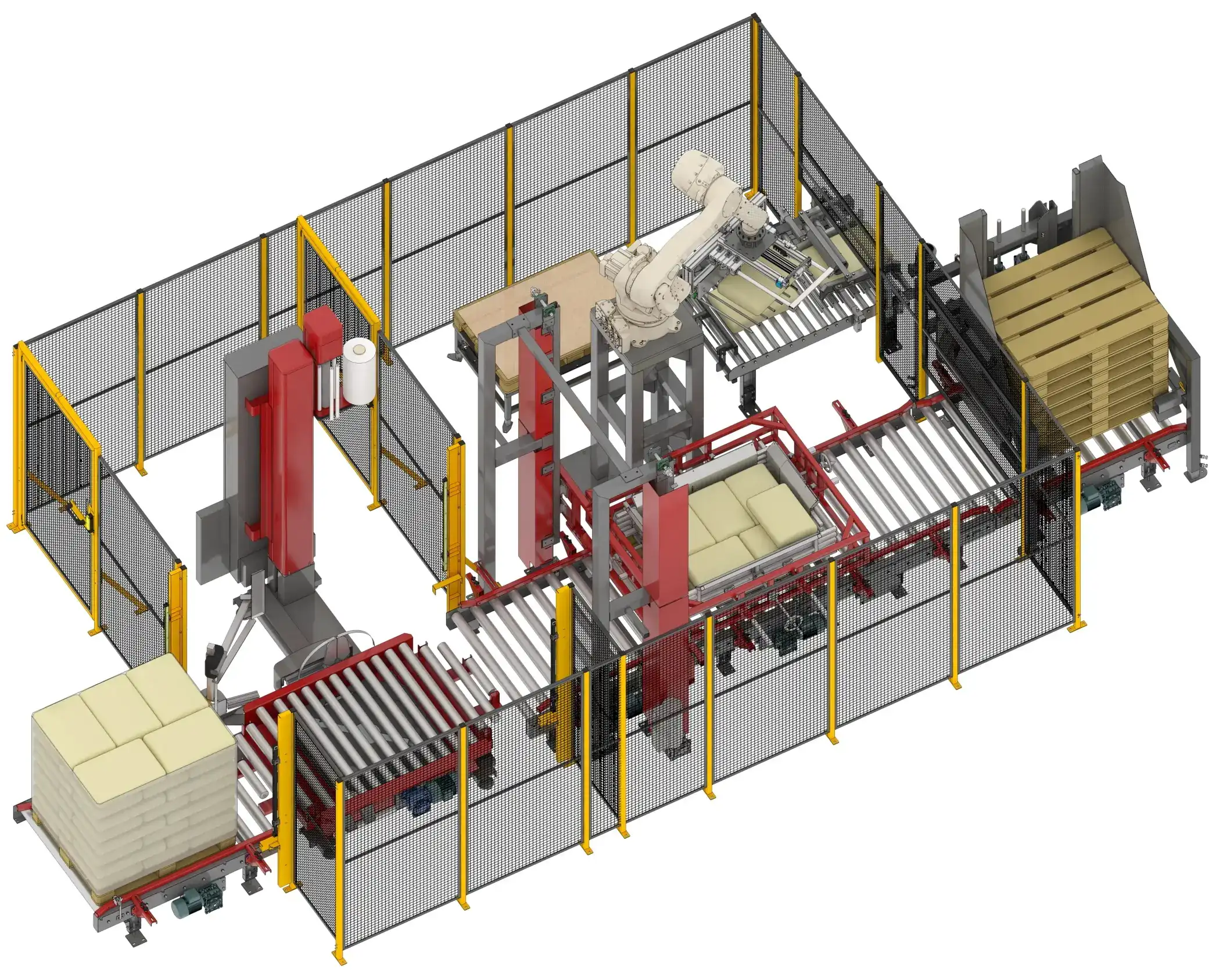

Bag placement on pallets

PR1-W is an advanced bag palletizer developed from years of market observation and analysis of the challenges faced by producers who pack products in various types of bags. Our solution enables automatic stacking of bags weighing from 4 to 15 kg.

Bag palletizing station

The bag palletizing station consists of:

- Industrial robot

- Elevator with a forming unit

- Automatic pallet transport

- Bag conveyor

- Safety fencing

Possible extensions include:

- AUTOMATIC PALLET MAGAZINE – up to 13 pcs.

- PALLET CROSSINGS – chain or roller

- SHEET MAGAZINE – the robot can also pick sheets from a stack

- PALLET WRAPPER – turntable, arm, or hood type

"Due to the diverse shapes of vegetables, palletizing these products is an extremely demanding process. Observing the market and the challenges faced by producers, Domasz Robotics responded with an advanced solution that enables the automation of palletizing potatoes, onions, and more. The basic version can be expanded with components such as an automatic pallet magazine, pallet wrapper, bag feed conveyor system adapted to individual requirements, and an additional buffer for full pallets."

Kamil Mandrela, Project Manager and Co-owner

Ensure freshness and safety of your products.

Check out DrewnianeSkrzynie.com.pl - Certified wooden pallet boxes for fruits and vegetables, custom-made.

Machines and projects implemented for our clients are insured by Warta.

DOMASZ ROBOTICS Sp. z o. o.

ul. Centralna 16

63-012 Dominowo

Wrocław Branch

ul. Prosta 36C

53-508 Wrocław

Kamil Mandrela

Machine Specialist

+48 797 628 965

Wiktoria Pawlicka

Younger Administration Specialist

+48 789 166 923