Granular materials

Granular materials are an integral part of various industries, such as food, chemical, and construction. Palletizing these materials poses unique challenges for manufacturers and logistics.

Bulk materials, such as grains, powders, or granules, feed and feed products, exhibit variations in weight, density, and shape, making precise pallet stacking a challenge. Additionally, their instability and tendency to settle require specialized solutions to ensure safe and efficient palletizing.

At Domasz Robotics, we offer advanced technologies for palletizing bulk materials, enabling precise pallet stacking regardless of material variations. Our innovative solutions provide cargo stability, minimize material loss, and enhance palletizing efficiency.

With our advanced bulk material handling systems, optimal utilization of pallet space, risk reduction, and quick adaptation to different material types are achieved. Our team of experts is ready to collaborate with clients, understand their specific needs, and provide optimal solutions to meet even the most demanding challenges of bulk material palletizing.

Explore our advanced solutions for palletizing granular materials and join our wide range of customers who achieve higher efficiency, quality, and safety in handling these specific materials.

Benefits of automatical palletization with usage of an industrial robot:

- Minimal space required for the workstation

- Relief of workers from heavy and monotonous work

- Increased efficiency in stacking bags on pallets

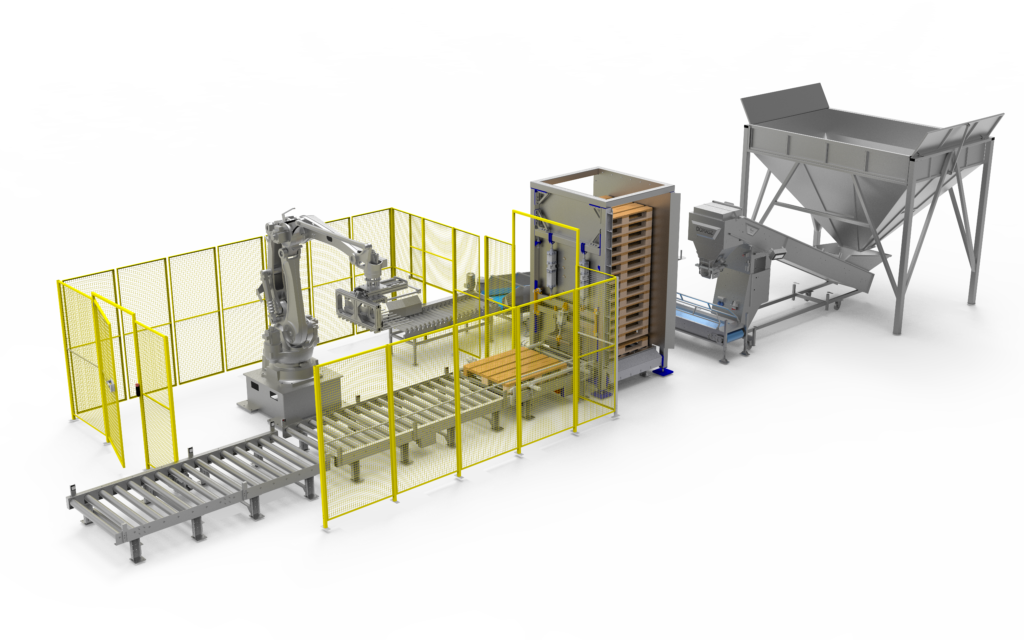

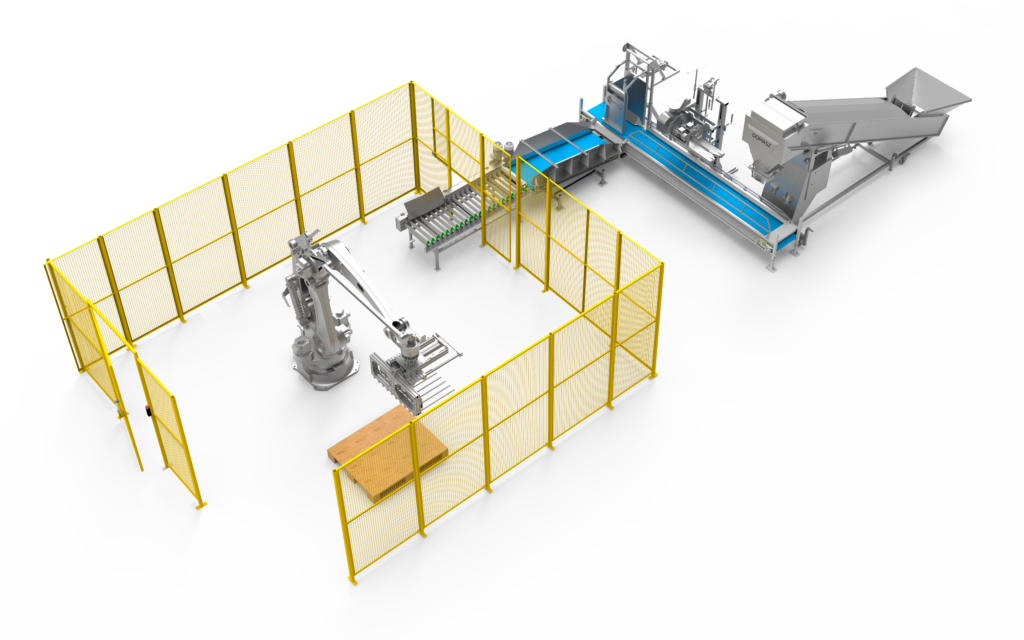

When preparing an offer for a robotic position, we conduct a thorough analysis of the needs and create visualizations. Examples below:

A robotic stand is composed of:

- Industrial robot

- Gripper tailored to the specific application

- Transport, such as rollers and conveyor belts

- Safety elements, such as safety controllers and barriers

- Automation elements, such as controls, HMI panels, and PLC controllers

The palletizing efficiency using industrial robots can reach up to 12,500 kg per hour!

Example realisations

COAL BAG PALLETIZING – EUROCARBO HUBERT JANAS

Key features and parameters of the workstation:

- DOMASZ weighing and bagging machine

- 25 kg polypropylene bags

- Bag sliding gripper

- Magazine for 15 empty pallets

- Automatic pallet entry for palletizing

- Automatic exit for full pallets

- Buffer area for full pallets

SOYBEAN MEAL BAG PALLETIZING – SANDO MARIUSZ ZANIEWICZ

Key features and parameters of the workstation:

- DOMASZ weighing and bagging machine

- 25 kg polypropylene bags

- Bag sliding gripper

- Magazine for 15 empty pallets

- Automatic pallet entry for palletizing

- Automatic exit for full pallets

- Buffer area for full pallets

PELLET BAG PALLETIZING

Key features and parameters of the workstation:

- 15 and 25 kg plastic bags

- Forklift type gripper

- Manual loading of empty pallets and retrieval of full ones