Vegetables and fruits

Vegetables and fruits pose unique challenges in packaging due to their diverse shapes, sizes, and delicate structures. At Domasz Robotics, we fully understand the specific nature of these products, which is why we have developed solutions tailored to their requirements. Our advanced palletizing and handling systems enable precise and efficient packaging of vegetables and fruits, ensuring optimal protection during storage and transportation. Regardless of the type of packaging, our solutions provide stability and safety for vegetables and fruits, maintaining their quality and freshness at the highest level.

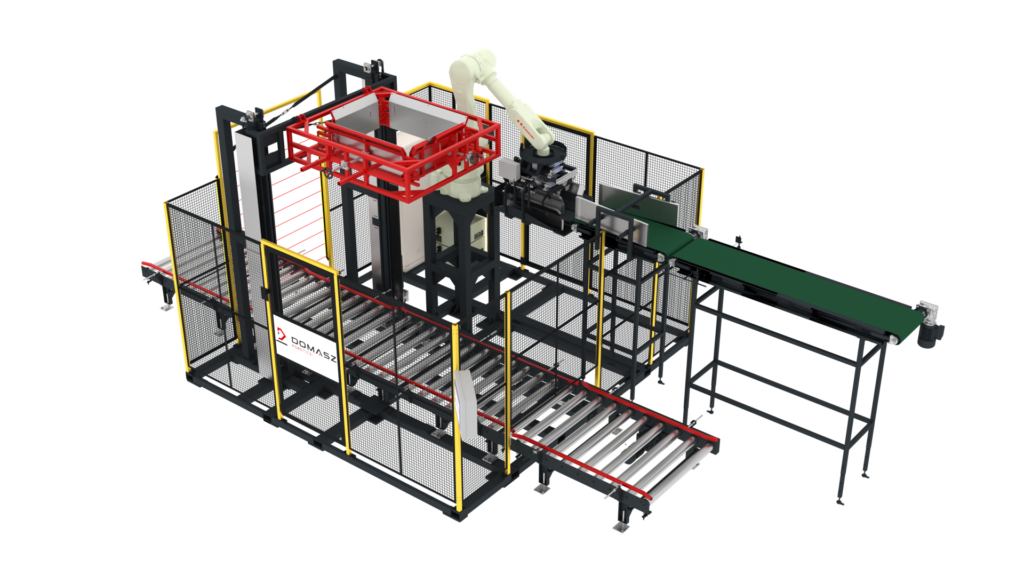

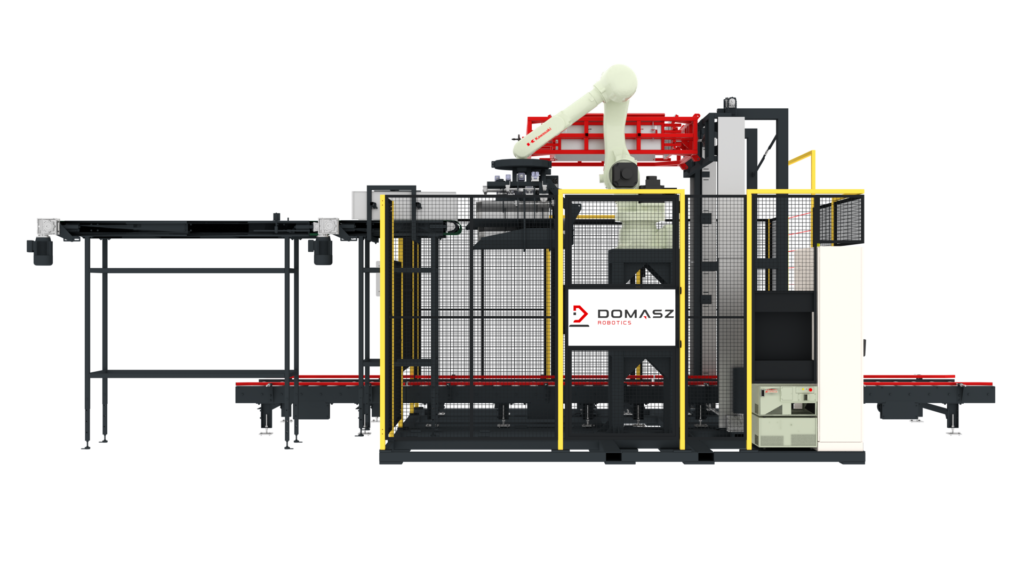

PRODUCT DESCRIPTION

- PR1-W is an advanced bag palletizer developed based on years of market observation and analysis of challenges faced by manufacturers who pack their products in various types of bags. Our solution allows for automatic stacking of bags weighing from 4 to 15 kg.

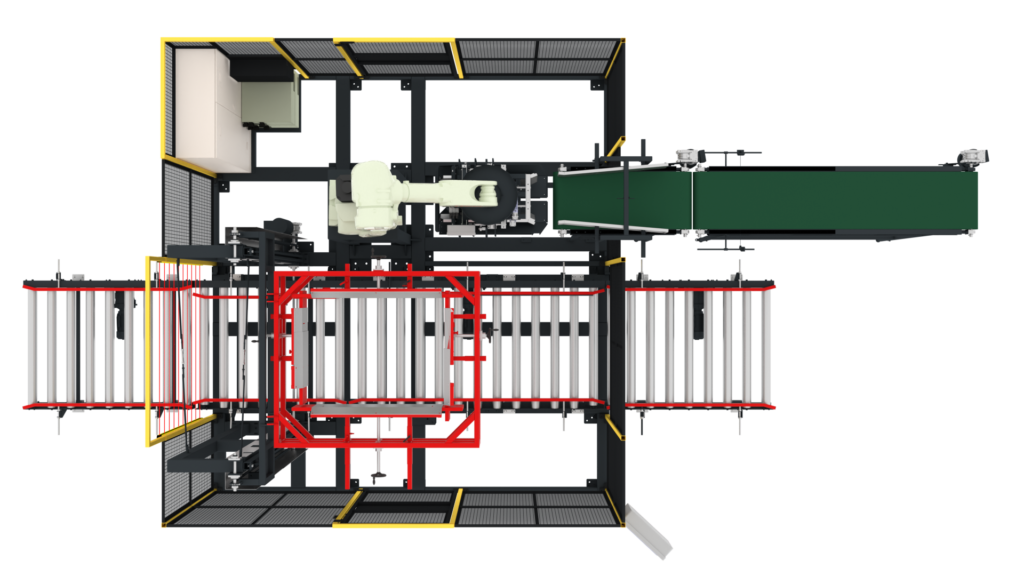

- The PR1-W palletizer, created by our company, is optimized for picking up and stacking bags made from various materials, ranging from paper, through plastic, to woven or jute bags. The bag stacking process takes place inside an adjustable forming unit, ensuring the creation of even pallets regardless of the bag volume variability, the structure of the packed material, or the type of packaging.

- Our machine enables palletization on two of the most commonly used types of pallets: Euro pallets and standard industrial pallets. As a result, our solution is extremely flexible and adapts to the individual needs of different manufacturers who use various types of pallets for storing and transporting their products.

BENEFITS

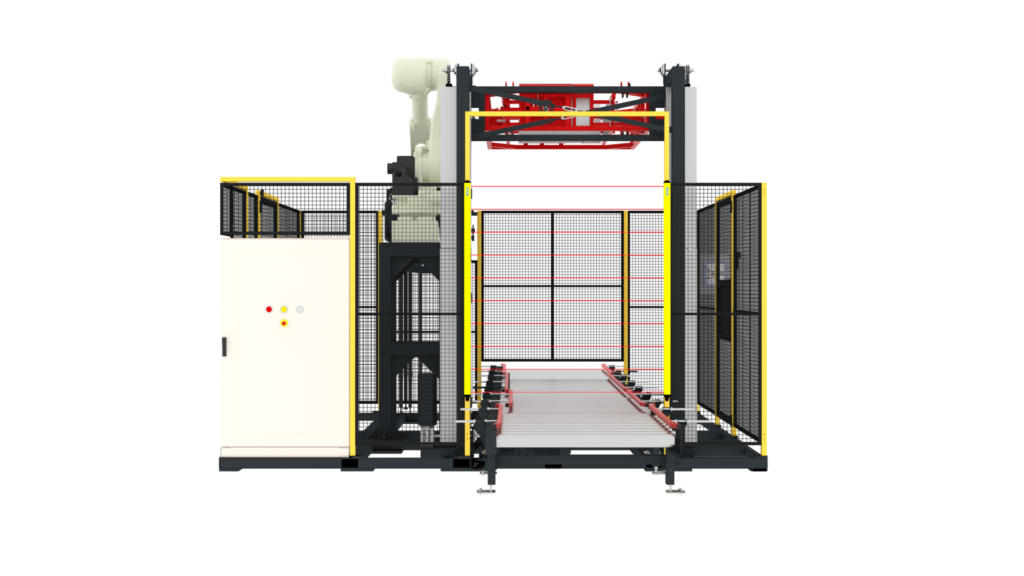

- High stability of stacked pallets achieved through collar forming

- Mechanical adjustability of stack dimensions for easy loading of pallets

- Increasing profitability through robotics relief – learn more: click here

- Wide range of adjustments facilitated by the use of an industrial robot

- Easy operation through a touch screen with the ability to create custom palletization recipes

- Ensuring full operator safety through the use of SICK Safety components

TECHNICAL SPECIFICATION

| Bags range | Up to 15kg |

| Efficiency | Up to 9 t/h (depending on the packaging) |

| Stacking height | Up to 2m (with pallet) |

| Bag type | raschel, paper, foil, polypropylene, woven |

| Pallet type | euro – 1200x800mm industrial – 1200x1000mm |

| Environmental conditions | 0-40°C |

| Pneumatical connection | min.6 bar – 80 NL/min |

| Electrical connection | 3×400 N PE 50Hz |

| Power consumption | 8kW |

| Dimensions | 7300x3900x2950 |

Example realisations

In order to prepare an offer: click here